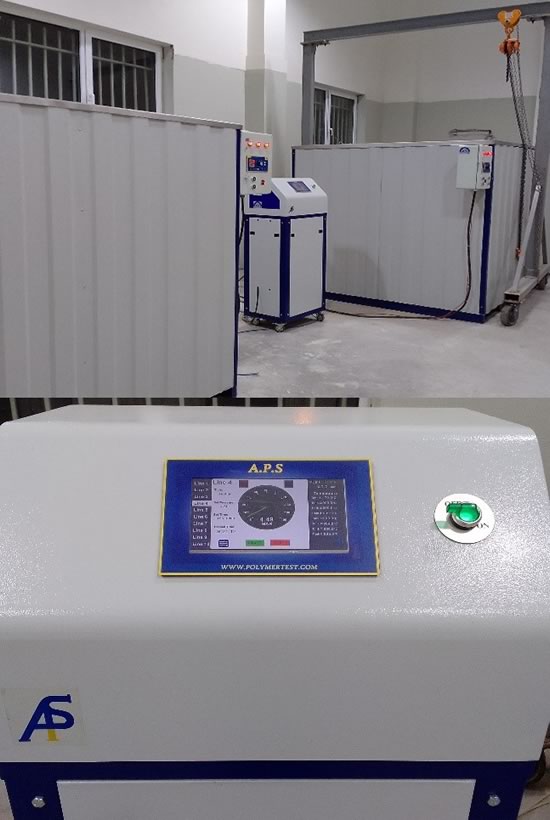

Longitudinal reversion test

Thermoplastic tubes are stressed by waste stress during the cooling of the production process. The aim of the test is to determine the method for measuring the longitudinal return of thermoplastic tubes during reheating. In this test, 20 cm of polyethylene pipe is marked and placed in the Avon with a known temperature of 110 °C (HDPE) for several hours (according to the thickness of the polyethylene pipe wall) and after testing and cooling at ambient temperature, the longitudinal changes of the sample are measured by caliper. The maximum allowable percentage of changes is 3%.

According to the standards:

National standard of Iran INSO: 17614

Latin reference standard ISO: 2505