Azma Plas manufactures a variety of polyethylene and polypropylene pipes

Azma Plas has been started in 2015 with the aim of producing a variety of polyethylene and polypropylene pipes using up-to-date knowledge and new technologies.

Currently, the construction and completion stages of the project are carried out in Shams Abad Industrial Town and the main equipment of production lines has been supplied from European countries and reputable global brands. The size of the products in the polyethylene pipes section is from 16 to 1200 mm and the equipment with the latest technologies has provided the possibility of producing new and quality products. Currently, with the progress of the work and the commissioning of the first phase, pipe sizes of 16 to 1200 mm have been produced, and in the next steps, other pipe sizes are produced. We always hope to take steps to improve the type and quality of products with efforts and future activities.

Nafis Polymer Arna Co., Ltd. with the brand “Azmaplas”

Previous activities of managers in the field of market and successful experience of the past 35 years in the field of production and supply of similar products and concerns of daily innovation in the mentioned industry to gain appropriate market share from the region and Iran in the field of production of various polyethylene pipes including gas, water, sewage, and related fittings are assured.

Also, choosing a unique product based on international standards and advanced technology in the field of new products including polyethylene multilayer pipes, and anti-crack pipes, and creating new installation methods based on the mentioned pipes has created a suitable target market. Due to the rich oil and gas resources in the country and the competitive advantage in the production of petrochemical products, downstream industries have good advantages for growth.

The necessity of economic evaluation in water resources procurement and development projects is the limitation of facilities in different fields and the diverse and widespread needs of society. The principle of limitation of facilities and breadth of needs raises the question of choice and necessity of decision-making based on economic logic.

Also, due to climatic conditions and the time and place of water, sewage, and gas in Iran, the plans for supplying and developing these networks will have significant growth.

In this regard, paying attention to the optimal use of water in agricultural industries as well as the use of new irrigation methods and recycling of wastewater in sewage networks can lead to many problems.

The field of investment in the development of gas pipelines has been considered in recent years and the country’s basic need for access to appropriate fuel through these networks is provided.

Considering the new technologies in the field of polyethylene pipes in the world and the need to use these items for use in the production of domestic products and to achieve appropriate export fields, Nafis Field Arna Industries Co. has defined the mentioned project in Shams Abad Industrial Town.

The selection of this town is based on access to roads and lines suitable for export and centrality for supplying products to consumers.

The product studied in this project is polyethylene pipes and fittings, code 3 of which is 25201222.

These products include multilayer and single-layer polyethylene pipes as well as corrugate sewage pipes and polyethylene gas pipes.

The size of pipes in the products is from 16 mm to 1200 mm in diameter for gas and water pipes and up to 2500 mm in diameter for corrugate pipes.

The standards used are the criterion of action:

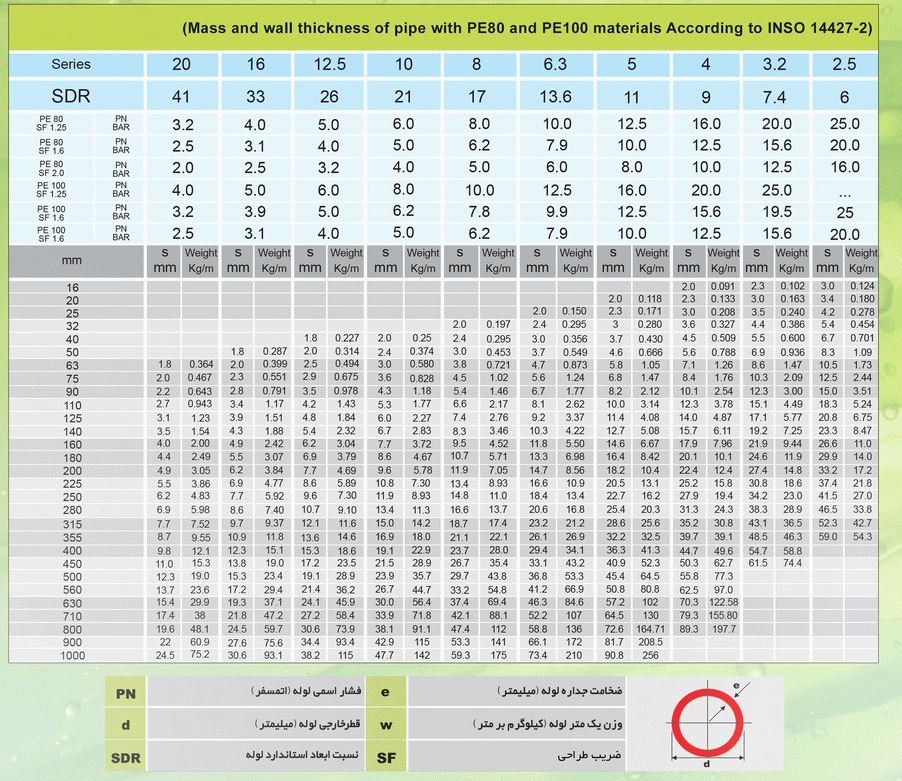

1- The latest edition of The Institute of Standards and Industrial Research of Iran (Standard 14427)

2- Drinking water standard of Program and Budget Organization, Ministry of Energy

3- Standard of gas supply pipes – Iran National Gas Company

4- BS-En standards (1555 and 12201)

5- 14427- Polyethylene Standard No. 1, Part 1: General (PE)

6- 14427- Polyethylene Standard No. 2, Part 2: Pipes (PE)

7- 14427- Standard No. 3, Part 3: Connections (PE)

8- 14427- Standard No. 4, Part 4: Faucets (PE)

9- 14427- Standard No. 5, Part 5: System Efficiency – (PE)

10- 14427- Standard No. 7, Part 7: Conformity Assessment Guide – Ethylene (PE)

11- 7175-Plastics standard number 1, polyethylene pipes used in water supply, measuring the dimensions of the test method

12- 7175- Plastics Standard No. 2, Polyethylene pipes used in water supply, measuring the amount of soot, test method

13- 7175- Plastics Standard No. 3, Polyethylene pipes used in water supply, thermal return measurement – test method

14- 7175- Plastics Standard No. 6, Polyethylene pipes used in water supply – Investigating the distribution of soot, test method

15- 7175- Plastics Standard No. 8, polyethylene pipes used in water supply – resistance to crack growth caused by the combination of stress and environmental factors – test method

16- Standard No. 14563 Plastics – Plastic pipes and fittings – Pressure reduction coefficients in 20 C polyethylene pipeline systems used in extreme temperatures

17- Standard No. 12439 Assembly connections with mechanical connection parts – requirements and method (PE) of polyethylene pressure pipes, internal low pressure test (leakage to the inside)

18- Standard No. 12440 Leakage test under – (PE) assembly connections between connecting parts and polyethylene pressure pipes under internal pressure.

19- Standard No. 13502 Leakage test under – (PE) assembly connections between connecting parts and pipes under polyethylene pressure, internal pressure and subject to bending

20- Standard No. 13316, resistance test against – (PE) assembly connections between connection parts and polyethylene pressure pipes jumping out.

21- Standard No. 14474 Plastics – pipes and fittings – pressure fittings with mechanical connection for polyethylene pressure pipes in water supply systems.

22- Standard No. 13183 and connector (PE) for plastic pipes and fittings – preparation of the test piece mounted between the polyethylene pipes

Electric welding

Also, regarding the standard parameters of the final product, the desired and maximum values are as described in the following table: